|

|

|

Ministry of

Education, Research and Youth Gheorghe Asachi Technical

University of Iasi Faculty of Chemical Engineering

and Environmental Protection PN-II-RU-TE-2014-4-0405, Nr. 274/1.10.2015 |

|

|||||||||||||||||||||||||||||||||||||||||||

|

Development and optimization of an innovative

photo-Fenton-peroxone system for degrading organic micropollutants in water |

||||||||||||||||||||||||||||||||||||||||||||||

|

|

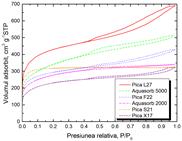

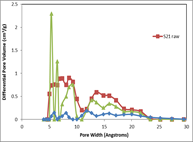

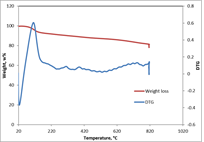

Project description The present project proposes the development and technical optimization of an innovative photo-Fenton-peroxone treatment system for degrading micropollutants from water and wastewater. WHO and UNEP signaled in 2013 the great threat of endocrine disrupting micropollutants. Among chemicals in use, around 800 of them have been identified as endocrine disrupting compounds. Some chemicals known as non-harmful might become toxic in mixtures. The main sources of endocrine disrupting compounds are represented by treatment plants of domestic wastewater (cleaning and personal care products), wastewater discharged by hospitals, rainwater, chemical plants, livestock and agriculture. More efficient, environmentally friendly and reliable treatment facilities for environmental factors are needed. Integrated studies (including operating costs and scaling up) with an emphasis on the optimization of advanced oxidation technologies are of critical importance all the more so as the new challenges in the field of water and wastewater treatment consists in the urgent need to dramatically increase the treatment efficiencies in relation to micropollutants. A reliable final polishing step system for wastewater treatment in relation to traces of a wide range of organic micropollutants will be developed. The novel features of the suggested photo-Fenton-peroxone technique consist in coupling heterogeneous photo-Fenton and in-situ-generated peroxone into a powerful oxidation system having also the capability to adsorb traces of non-organic micropollutants onto high-surface, porous composites. New Fe immobilized AC, Fe and Mn oxides, and Fe-doped Titanium dioxide coated AC will be investigated. Also, extremely high-surface aerogels and novel Fenton nano-oxides and doped-graphene coated aerogels will be developed. The most promising composites will be tested. The newly designed treatment system will be modeled and optimized. In the framework of 2015 stage of the present project the main methods and working procedures were established. Several organic compounds were selected as model micropollutants. Also, preliminary studies on the synthesis and characterization of Fe-impregnated GAC composites have been performed. Having different textural and chemical features, several activated carbon materials (PICA and Aquasorb Jacobi, France) were selected for the preparation of some composite by wet impregnation of Fe. The surface properties of the considered activated carbon matrices were analysed by means N2 adsorption-desorption isotherms.

The wet impregnation was carried out using a water thermostated bath provided with orbital shacking GFL 1092. Batch adsorption tests were performed on the same device. Table Fe immobilized on GACs by wet direct impregnation

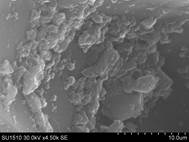

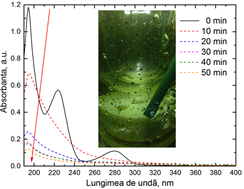

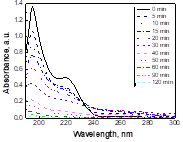

SEM images of GAC matrices emphasize the morphological changes due to the Fe impregnation. Photolysis and photo-catalysis tests to degrade some model micropollutants were performed using a laboratory UV-Consulting Peschl photo-reactor (medium pressure UV lamp).

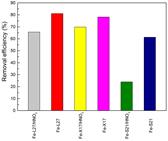

Fe-GAC composites were tested as Fenton-like composites with treatment efficiency in relation to 4-CP of over 98% after 30 min of UV irradiation. In the framework of 2016 stage iron-embedded composited based on GAC were synthesized and characterized. The main objective of the prior stage consisted in obtaining activated carbon composites impregnated with iron through the method of direct wet impregnation. In the present stage, all the activities of this objective were performed in order to obtain activated carbon based composites impregnated with Fe through oxidation with permanganate, and Fe doped TiO2 impregnated GAC composites. In addition, carbon based composites were prepared by Fe co-precipitation method in alkaline medium. Monoliths and particles of aerogel containing TiO2 doped graphene were prepared. The catalytic performance of these composites in relation to several model micropollutants, such as Ibuprofen, Diclofenac and Para-chlorophenol was established. These results were compared with those obtained by using novel Fenton-like catalysts based on Layered Double Hydroxides.

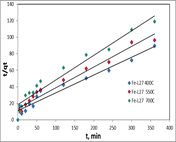

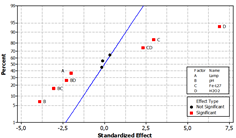

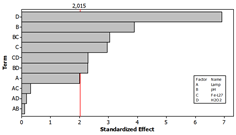

Within the stage of 2017 several new Fenton catalyst have been achieved and characterized. The experimental designs needed to evaluate the influence of the main parameters over the performance of photo-Fenton-peroxone process were established. Also, two experimental designs were created in order to mathematically model and optimize the degradation process operated in batch and continuous regimes, respectively. At first, a fractional factorial design was established for the degradation process of Ibuprofen molecule in order to establish the statistical significance of Fe-L27 (550 °C) catalyst dose, lamp type (Non-O3 and, O3 generating lamp respectively), hydrogen peroxide concentration as well as the initial value of solution pH. In order to screen the significance of the main factors and their interaction, Pareto and normal diagrams of the two responses were represented.

For the main factors and for

their ranges of variation considered in the experimental design, the order of

main effect significance over the treatment degree is in following: H2O2>pH

value> Fe-L27 dose>lamp type. If the importance of the effect of

hydrogen peroxide concentration is mainly due to its relatively wide rage,

the other three factors present effects of comparable magnitude, emphasizing

the performance of photo-Fenton-peroxone process in relation to its

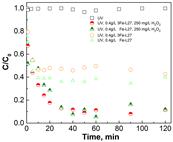

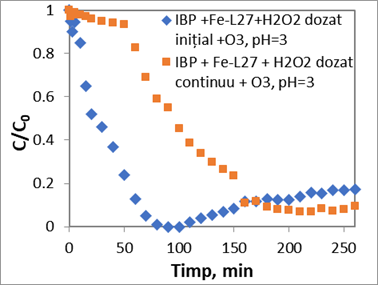

constituent oxidation processes. To conduct the experimental tests for micropollutant degradation by photo-Fenton-peroxone under continuous regime, an experimental micro-pilot set-up was designed and realized. The figure below presents the evolution Ibuprofen degradation in presence of Fe-L27 by the photo-Fenton-peroxone process conducted under continuous regime.

In case of Ibuprofen degradation it can be noticed a slightly slower decrease in concentration when the hydrogen peroxide is added continuously into the system. After 150 min a removal efficiency of 93% is reached, value that is relatively constant once the critical concentration of H2O2 is obtained in the reactor. When hydrogen peroxide is added at the beginning of the test, the degradation process reaches a maximum efficiency (removal efficiency of 100%) after 80 min. However, after 11 min, the generation of hydroxyl radicals decreases in intensity leading to a slight decrease in the value of removal efficiency. After 260 min of irradiation, a removal efficiency of 83% is obtained. Modeling of photo-Fenton-peroxone process, operated under continuous regime, was achieved by means of response surface methodology. A fractional central composite design for three factors was established. The catalyst dose ranged between 0.1 and 0.4 g/L, hydrogen peroxide concentration ranged from 100 to 500 g/L and the influent flow rate rate ranged between 0.3 and 3 L/h. The dependent variables (responses) were the removal efficiency and apparent constant rate. The

economical optimization of the photo-Fenton-peroxone process was carried aut

by means of a multi-objective method, the two objective functions being

maximized under the constraints of minimizing the value of two independent

variables: hydrogen peroxide concentration and catalyst dose. |

|||||||||||||||||||||||||||||||||||||||||||||

|

|

18.10.2017 |

|||||||||||||||||||||||||||||||||||||||||||||